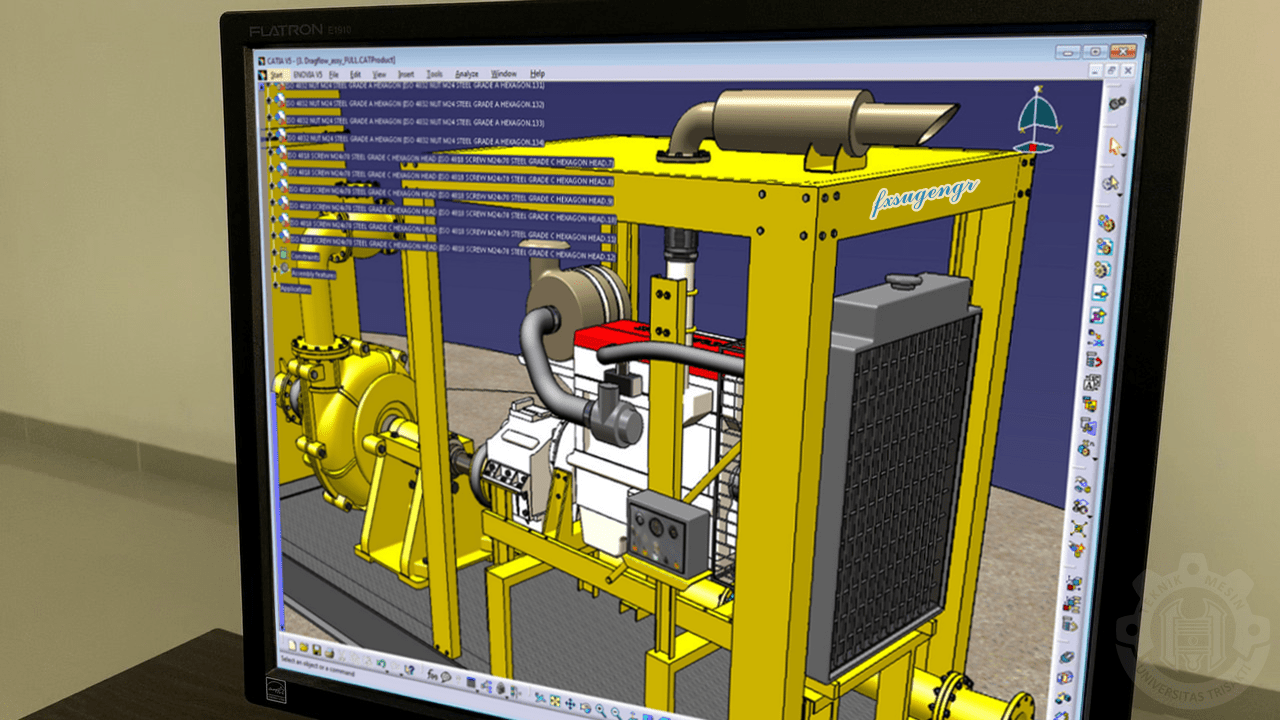

To organize CAD/CAM & CAE practicum to support the implementation of academic activities in the Mechanical Engineering Department, especially for courses based on computer design, visual model analysis, and product manufacturing with CNC machines such as:

- CAD/CAM course

- Advanced CAD/CAM course

- Product Design and Development course

- Fast Manufacturing course

- Mould Technology course

- CNC Programming course

In addition, it is also as a facilitator for lecturers and students to conduct scientific research and community service.